CNG HQ Rainford

Category: Commercial / Industrial

Company: Thomas Consulting

Client: CNG Fuels

Engineers at Thomas Consulting were commissioned by CNG Fuels to assist with the design of a new company headquarters in Rainford.

They were appointed to oversee the design from Phase 1, including design of the site levels along with the surface water and foul water drainage systems. They used Site3D throughout, overcoming a number of site-specific challenges.

JMP Architects' computer rendering of proposed HQ entrance

JMP Architects' rendering of the forecourts and loading bays

The Initial Challenge

The team faced a number of challenges whilst designing the plot. The first being the considerable size of the site. The design would require complex drainage to be able to treat, attenuate and discharge surface water.

“The main challenge from the outset was that the site was four hectares, which is quite a significant area when you’re designing the foul and surface water.”

– Scott Milligan, Thomas Consulting

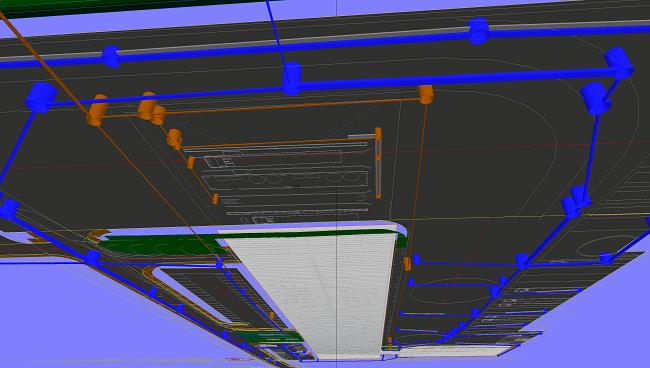

The large site consisted of around 70-80 different manholes and same number of drainage runs, but the team were still able to complete the design with relative ease using Site3D. The drainage aspects were simple to plot thanks to the drag and drop features, and Site3D gave the engineers a great visual representation of the pipe work. This made clashes in the surface water and foul water drainage easily identifiable. Site3D’s tools also allowed them to fully plot roads, kerbs, junctions, and pathways, enabling them to create a very accurate 3D model of the site.

Problem Solving in Site3D

“Site3D’s tools enabled us to fully plot the roads, the kerbs, the junctions, pathways and create a very accurate 3D model of the site. From this initial work, we were able to complete the following works with relative ease considering the scale of the site.”

– Scott Milligan, Thomas Consulting

Thomas Consulting were given a discharge rate by the lead local flood authority of only 7 litres a second. The team were able to achieve this in Site3D by proposing a Hydrobrake® Flow Control Chamber prior to the outfall which restricted the discharge rate to what they required. They also proposed Geocellular tanks beneath the forecourt to attenuate the water and prevent the water from backing up upstream of the Hydrobrake®, thus preventing flooding. Additionally, the size of the whole system meant that there was sufficient storage within the pipework to allow for a low discharge rate without causing flooding or mass surcharging.

Site3D screenshot of drainage from underneath the site

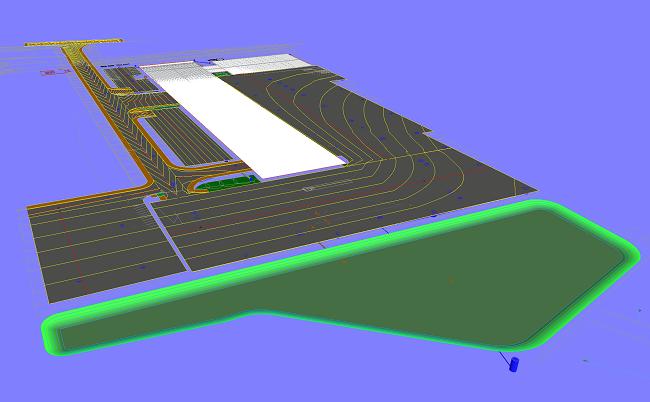

Site3D screenshot showing earthwork to the south of the site

Site3D as a Time Saver

A large portion of the site was in flood zones 2 and 3, and they had to navigate raising the entire site above the minimum flood zone level. Site3D’s cut and fill tool allowed the team create a large depression at the south of the site. This meant they could gauge the correct volume of material they would need in this area, so they could then add the right amount of land back into the site. Additionally, Site3D gave them the flexibility to test out different levels to see how this was reflected throughout the site. These tools and calculations in Site3D saved the team a considerable amount of time.

“Especially on the bigger sites like this, Site3D certainly did save a lot of time”

– Scott Milligan, Thomas Consulting

Communication and Flexibility

The engineers had to align their work with multiple consultants from different sectors, such as ecology and transport. Special consideration had to be given to where the surface water would go due to a valuable and protected animal species in the woodland to the south of the site. In addition, during the early stages of the design, they had to navigate through the woodland to a brook situated at the bottom of said woodland. This all meant constant correspondence with ecology teams and the council to ensure the design was viable.

“The software allowed us to easily update the model.”

– Scott Milligan, Thomas Consulting

With the longevity of the site, there were constant changes to the design, meaning communication with architects and the council was paramount. Site3D made any updates quick and painless. Furthermore, due to the entire site being modelled in Site3D, the team were able to gauge where the manholes and drainage runs were in relation to the building, making any revisions over the whole plot straightforward.

JMP Architects' rendering from new approach road

JMP Architects' rendering showing green planting and EV bays

Environmental and Ecological merits

The design can boast ecological and environmental feats, including the protection of the wildlife, and a commitment to achieving positive bio net gain which was accomplished by planting trees across the main area of the site. Additionally, this development would contribute to the shift of the renewable fuel sector.

In Summary

Thomas Consulting were able to use Site3D to complete the whole design for CNGHQ Rainford. The software’s intuitive and friendly interface enabled the team to work efficiently, making communication between different sectors easy. The team faced challenges including the large scale of the site as well as environmental factors, but were able to overcome any issues using Site3D’s extensive tools.